High-resistance pavement

At ECOINTELLIGENT SOLUTIONS, we transform unstable ground into solid and secure foundations. Our innovative and sustainable approach guarantees lasting results for your construction projects.

Ecodurfixsoil® is a cutting-edge additive designed to reinforce and protect any type of pavement, while mitigating dust and combating erosion. When combined with cement, it significantly increases the soil's mechanical strength and extends the lifespan of treated layers. Thanks to its advanced formulation, it can be used for a wide range of applications, including:

- Road infrastructure: road bases and sub-bases, esplanades and shoulders.

- Rural access and roads: private paths, farm roads, access routes to hotels or rural houses.

- Industrial and cargo areas: outdoor storage yards, heavy-duty transport tracks, and logistics platforms.

- Sports and leisure facilities: bike paths, horse riding trails, and greenways.

- Specialized construction: platforms for airfields, access to quarries, and roads for military or civil operations.

With Ecodurfixsoil®, you'll achieve a more cohesive, durable, and age-resistant surface, ready to withstand both light traffic and demanding industrial loads.

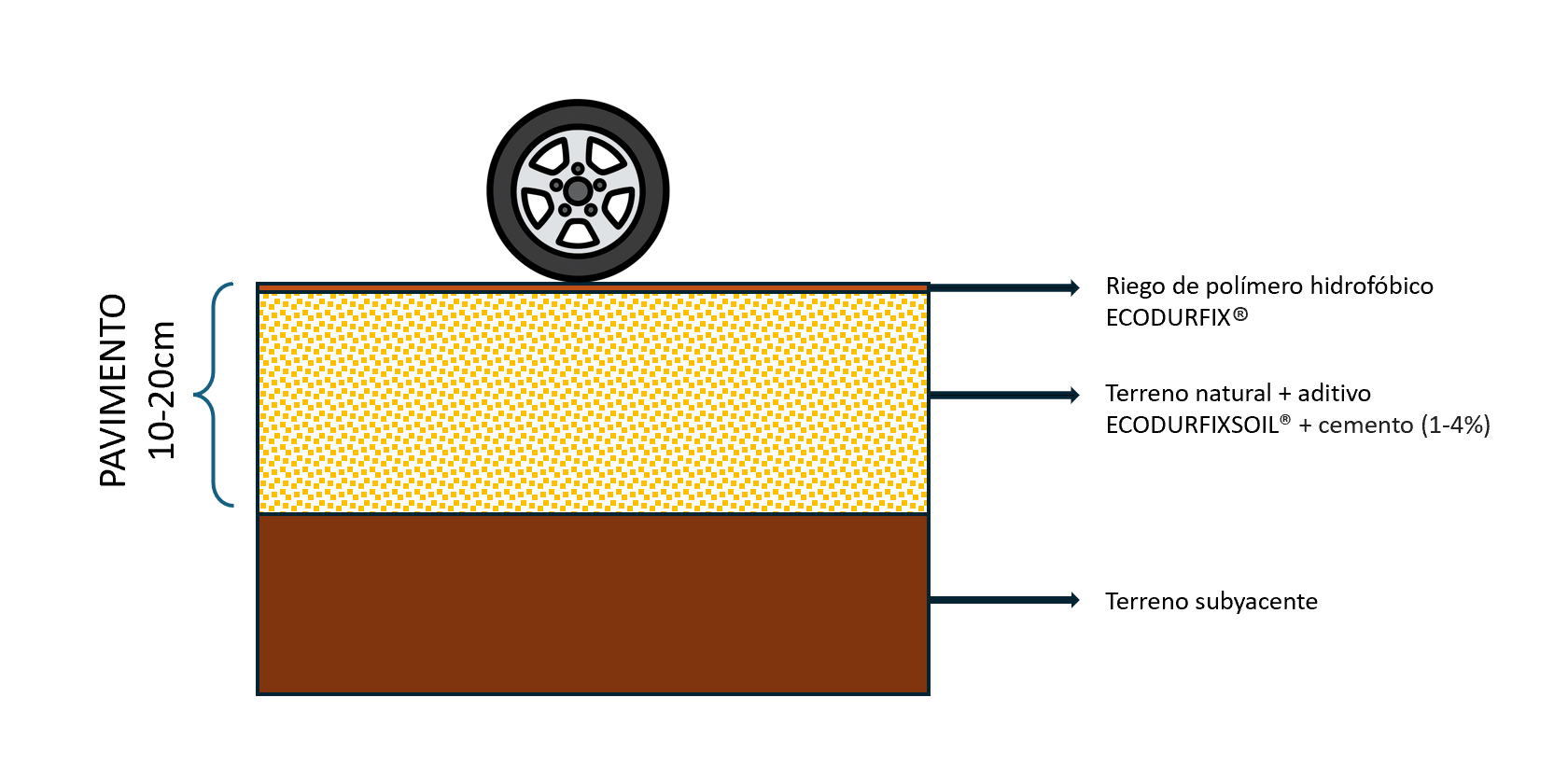

Technical Phases of Soil Stabilization with Ecodurfixsoil® additive

Milling the land in situ

- By milling in situ with a rotovator we break the surface crust and increase the porosity of the soil to improve its aeration.

Restart conglomerate

- Using a delivery truck equipped with a drum and volumetric regulator, cement is dosed between 1% and 4% by weight onto the granular surface, distributing it at low speed using rotating nozzles to ensure uniform coverage and immediate incorporation into the soil.

Homogeneous mixture

- Using a rotovator, the milled aggregate is mixed with the dosed binder in a single step, ensuring the homogeneity of the granular matrix and the fragmentation of agglomerates to optimize the cohesion and strength of the soil.

Ecodurfixsoil® irrigation homogeneous mixture

- Using a spray truck, the milled layer is watered with the Ecodurfixsoil® additive with the corresponding proportions of water until the optimum moisture content for compaction is reached, after which a rotovator pass is carried out to completely homogenize the mixture and ensure uniform distribution of the binder.

Profiling with motor grader

- Using a self-propelled motor grader, the surface is leveled until the desired slope, grade and regularity are achieved.

Compact

- It is compacted with a 10–12 t self-propelled smooth drum vibratory roller, making 2–3 passes per section and soil pressure adjusted to achieve at least 95% of the standard Proctor and ensure the elimination of air voids.

Surface irrigation with Ecodurfix®

- To promote the curing of the stabilized mix, light and uniform irrigation with Ecodurfix® diluted in water is carried out using nebulizers until the surface humidity is maintained between 75 – 90% of its field capacity, to optimize the cement-polymer reaction and maximize the strength gain.

Final result

- After completing all stabilization and sealing steps, let the surface rest without traffic for 24 to 48 hours, adjusting the drying time according to the ambient temperature (shorter for >25°C, longer for <15°C) to ensure optimal strength development and formation of the binder film.

Do you have any project in mind?

Complete the form below and discover how our solutions can make a difference!