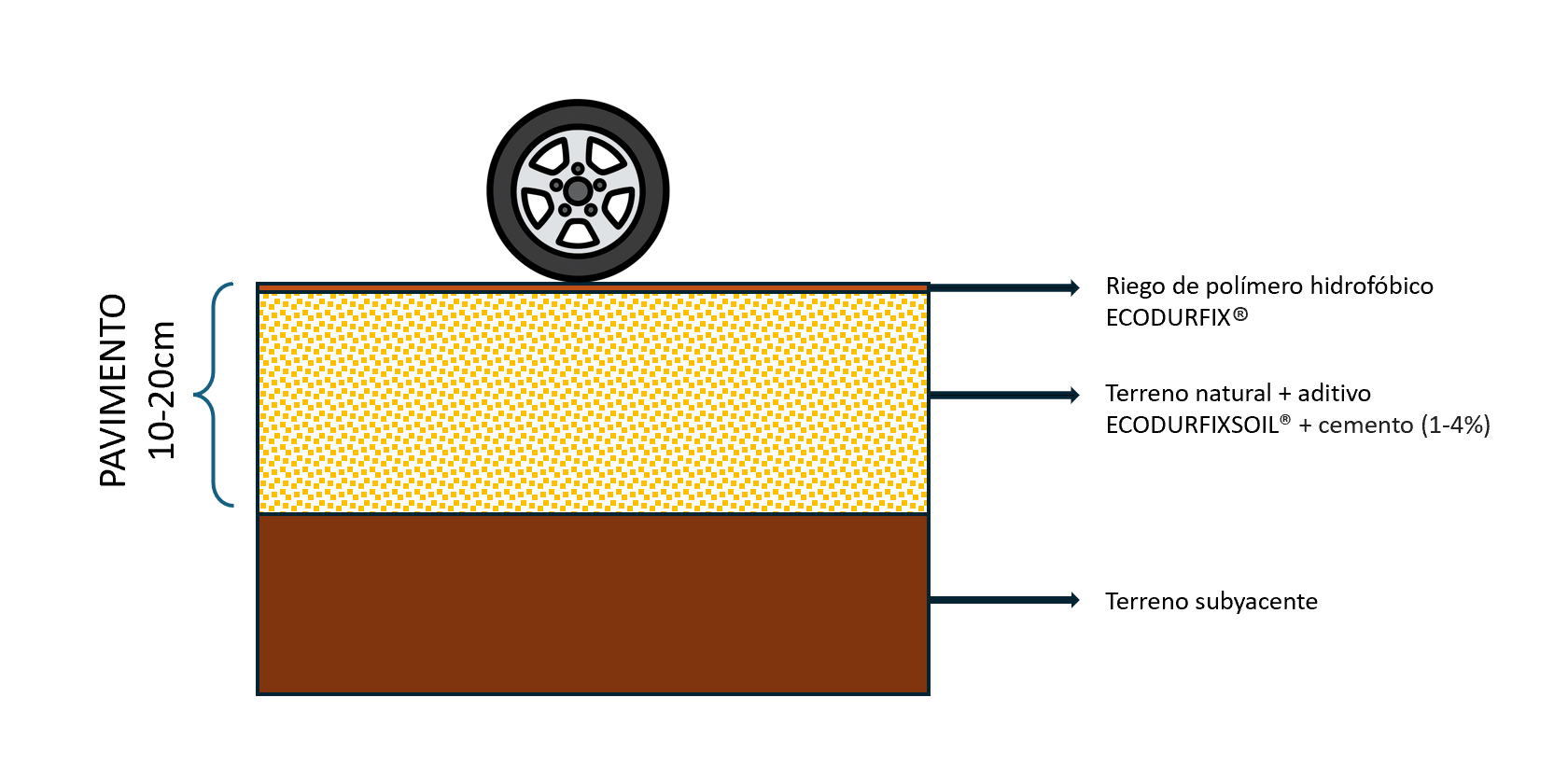

Technical pavements to support heavy loads and traffic

EcodurfixSoil® is a cutting-edge stabilizing additive formulated to reinforce and protect all types of soils classified in the AASHTO table. It reduces dust formation, combats erosion, and, when combined with a binder such as cement or lime, significantly improves the mechanical strength of the pavement and extends its useful life.

Thanks to its advanced formulation, it allows a wide variety of applications:

✅Road infrastructure: road bases and sub-bases, esplanades, shoulders, and temporary roads.

✅Access and rural roads: trails, farm roads, routes to hotels, rural houses, and agricultural areas.

✅Industrial and loading areas: outdoor yards, logistics platforms, warehouse access, and heavy-traffic areas.

✅Sports and leisure facilities: green paths, horse riding trails, and bike paths in natural surroundings.

✅Specialized construction: stabilization of airfield platforms, quarry access, and roads in military or industrial environments.

With Ecodurfixsoil® you will get a more cohesive, resistant and durable floor, suitable for both light traffic and heavy industrial loads.

Advantages

| Concrete | Loose Gravel | Stabilized soil with Ecodurfixsoil® | |

|---|---|---|---|

| Natural aesthetics | ❌ | ✅ | ✅✅ |

| Endurance | ✅✅ | ❌ | ✅✅ |

| Impermeability | ✅ | ✅✅ | ✅✅ |

| Maintenance | Low | High | Very low |

| Price €/m² | High | Low | Half |

Visible results With EcodurfixSoil® we transform unstable roads into durable, aesthetically pleasing surfaces ready to withstand daily traffic.

Advanced technology at the service of the soil

In our projects, we use state-of-the-art professional machinery capable of guaranteeing homogeneous mixtures, precise application, and a high-quality finish. We are committed to technical innovation to achieve more stable, durable, and sustainable floors.

Technical Phases of Soil Stabilization with Ecodurfixsoil® additive

Milling the ground in situ

- Using a rotovator, we break up the surface layer and increase the porosity of the soil, promoting aeration and facilitating homogeneous mixing with the additive.

Restart conglomerate

- Using a delivery truck equipped with a drum and volumetric regulator, the cement (between 1% and 4% by weight) is dosed onto the granular surface, distributing it at low speed using rotating nozzles to ensure uniform coverage and immediate incorporation into the soil.

Homogeneous mixture

- Using a rotovator, the milled aggregate is mixed with the previously dosed conglomerate in a single pass, ensuring the homogeneity of the granular matrix and adequate fragmentation of agglomerates, which optimizes the cohesion and strength of the soil.

Ecodurfixsoil® irrigation homogeneous mixture

- Using a spray tanker truck, the milled layer is sprayed with EcodurfixSoil® additive diluted in water until the optimum moisture content for compaction is reached. A rotovator is then used to ensure a homogeneous mixture of the aggregate and the binder and even distribution throughout the treated layer.

Profiling with motor grader

- Using a self-propelled motor grader, the surface is profiled to adjust the slope, grade, and evenness, ensuring the designed geometry and an optimal base for final compaction.

Compact

- Compaction is carried out using a self-propelled smooth-drum vibratory roller (10–12 t), applying 2 to 3 passes per section. The working pressure and moisture content are adjusted to achieve a minimum of 95% of the standard Proctor, ensuring the elimination of air voids and optimal density.

Surface irrigation with Ecodurfix®

- To promote the curing of the stabilized mix, a light, uniform spray of Ecodurfix® diluted in water is applied using misting nozzles. The goal is to maintain surface moisture between 75% and 90% of the field capacity, thus optimizing the cement-polymer reaction and maximizing strength gains.

Final result

- After completing all stabilization and sealing steps, the surface must be left untouched for 24 to 48 hours. This drying time should be adjusted according to the ambient temperature: shorter if >25°C and longer if <15°C, to ensure optimal strength development and the formation of the binder surface film.

Do you want to know if your soil is suitable for stabilization with EcodurfixSoil®? Tell us about your situation and we'll help you without obligation.

Block of Certifications and Technical Tests

Our flooring has been validated through resistance tests conducted in external laboratories under UNE-NLT standards. If you'd like to see detailed results, please contact us and we'll provide them to you without obligation.

Frequently Asked Questions

How long does a stabilized soil last?

A properly stabilized soil maintains its mechanical properties and impermeability for more than 3 years, and even 5 years or more, depending on traffic and weather conditions, and also on the annual maintenance required.

Can it be applied on any type of terrain?

In general yes: polymers improve the cohesion and resistance of sands, silts and even clays of low-medium plasticity.

Can I see laboratory resistance tests?

Of course. If you'd like to check the technical lab results, please contact us by email at tecnico@solucionesecointeligentes.es and we'll send them to you without obligation.

Does it require maintenance?

Virtually none. Being rigid and impermeable, the pavement withstands heavy traffic and rain without the need for recompaction. Maintenance would consist of surface watering once a year to extend the pavement's lifespan (maintenance is optional but recommended).

What advantages does it have over concrete?

Soil stabilization offers a more economical and faster solution than concrete, as it utilizes the in-situ material and completes the treatment in 1–2 days with no setting time. Its rigid, impermeable pavement requires virtually no maintenance, generates fewer emissions and waste, and allows additive dosages to be adjusted to each soil type, while also minimizing the risk of cracking due to differential settlement.

Is the stabilization system environmentally friendly?

Yes. We use technical additives and formulas that respect the environment, avoid the use of excessive asphalt or cement, and promote the natural integration of the pavement.

What type of traffic does it support?

Our solutions are designed to withstand everything from pedestrian use to heavy traffic, depending on the product and structure design.

How long does it take to be ready for use?

Describe the article or answer the question so interested visitors can learn more. You can highlight this text with bullet points, italics, bold, or by adding links.Can it withstand the passage of heavy vehicles?

Yes, our systems can stabilize soils for intensive use, including heavy machinery and vehicle traffic, provided the appropriate solution is applied to the terrain type.

What maintenance does a stabilized soil need?

Very little. Periodic checks are sufficient to correct specific erosion, add sealant if desired, and perform surface cleaning in high-traffic areas.

Can it be applied on clayey, stony or very dry soils?

Yes. We adapt the formula and dosage of our additives to the soil composition to always achieve a durable and functional surface.

Do you have a project? Tell us about it and we'll help you without obligation.

Contact Us

At Soluciones EcoInteligentes, we specialize in soil stabilization with ecological additives for rural roads, industrial areas, and sustainable pavements. Our products, such as Ecodurfixsoil® and Ecodurfix®, transform granular soils into strong and durable pavements suitable for heavy traffic, while respecting the environment and reducing the use of traditional materials such as asphalt or concrete.